How can we help you?

A Loudspeaker Driver Breakdown

- September 27, 2017

- Loudspeakers

Any loudspeaker driver is essentially an electric motor. It takes an electrical signal as input, generating motion (and sound) output. Unlike a battery’s steady input causing a wheel to continually spin, we vary the input with a signal generated from an original sound source.

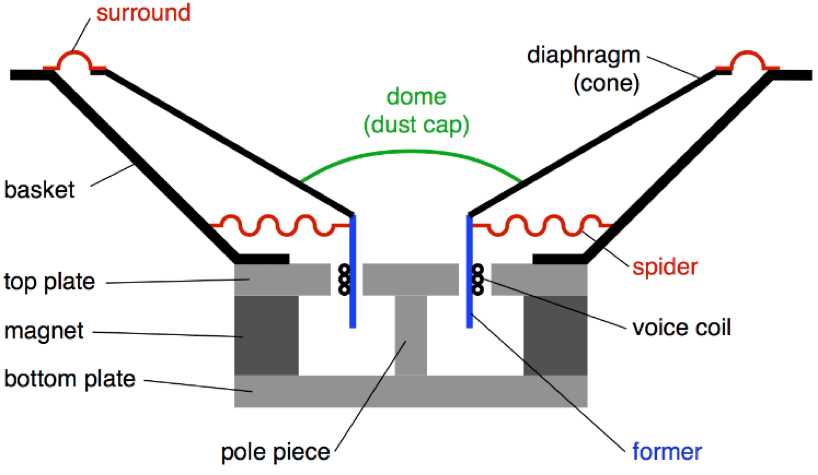

The motion starts with the interaction between a current-carrying conductor, the voice coil, in a pre-existing magnetic field between the top plate and the pole piece. In high school physics, we learn of the Lorentz motor principle (who said we’d never use this again?!) that describes this interaction. A live wire in a magnetic field feels a force proportional to the current, the wire length, and the field strength. Since the current is varied by the source, the product of the wire length, l, and field strength, B – the B·l constant – is a critical parameter of the loudspeaker driver that determines the resulting motion. Now, this force is maximised when the directions of the conductor and magnetic field are held perpendicular to each other. Wrapping a thin wire several times around a cylindrical former helps to both increase that conductor length and, when supported properly, maintain this perpendicular orientation. Those add-ons to the magnet (top and bottom plates, pole piece) just provide a means to channel the magnetic field into the space around the voice coil. The shape of the magnet assembly can vary with magnet type (ferrite, Nd-Fe-B, etc.) but the function is the same.

Now, if only the voice coil moves, there wouldn’t be much sound. Sound requires air movement. This is the purpose of the diaphragm. The larger diaphragm surface area pushes more air, generating more sound. But this comes at a cost. Again, going back to high school physics, Sir Isaac Newton tells us that more mass needs more force to move and the larger diaphragm has more mass. The diaphragm material (paper, mylar, etc.) can impact this mass as well. Things to consider when designing that coil-magnet combination.

Okay. So, we can generate motion with the voice coil and magnet. And this motion is transferred to the air by the diaphragm. Now, the challenge is keeping that voice coil in that magnetic field. After all, if it moves out of the field, it no longer interacts with it. Enter the surround and spider. These serve a common purpose. Each acts as a spring (with compliant materials like urethane foam or santoprene) opposing this motion the farther the voice coil moves from the center of the magnetic field. Everything is balanced when the coil is in the center of the field. But, just like an elastic band gets tighter as you stretch it, this suspension does exactly the same. And, when the signal stops, the voice coil returns the center of the field.

Holding everything together is the basket, which is a rigid frame of metal, plastic or some composite material. The fixed ends of the spider and surround are attached here, as is the magnet structure. When we analyze the sound from the driver with a varying input signal, we’ll see that the mass of the diaphragm, surrounding air, and coil, along with the compliance of the surround/spider suspension, play a significant role in its performance. The basket should be rigid enough to have minimal impact on this performance. And, while that dust cap adds subtle acoustic nuance, its main purpose is described by its name – it just keeps stuff out of the magnet gap to allow the voice coil in the loudspeaker to move freely.

Have questions? Let us help. We are your source for audio solutions.

Email: contact@Stetron.com

Customer Service: Canada: 1-877-716-0751 U.S.A: 1-800-925-3002.

Log In

Log In Register

Register Favorites

Favorites