How can we help you?

Thiele-Small Parameters: The Measurement

- January 16, 2018

- Loudspeakers

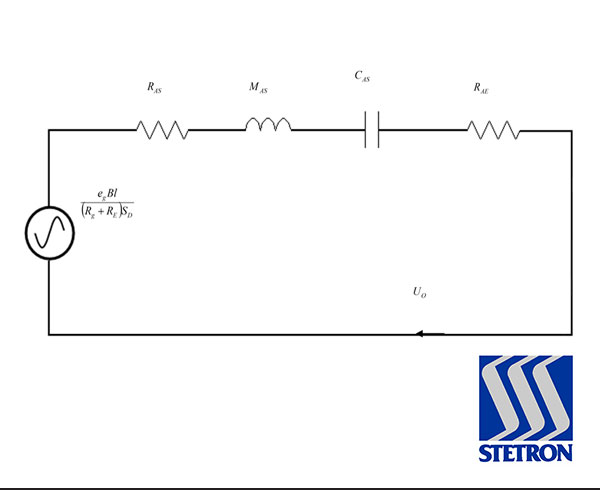

So, modeling a loudspeaker driver’s low frequency performance is readily accomplished with an analogous R-L-C circuit. But these circuit components are amalgams of the interaction between the electrical, mechanical, and acoustic aspects of this energy conversion. Interestingly, though, Thiele, Small, and several other audio researchers and audio engineers have determined an ingenious methodology for gleaning these composites from a few simple measurements of the voice coil impedance and how it varies near the driver’s resonant frequency. These Thiele-Small, or TS, parameters are all that’s needed to accurately model a loudspeaker’s frequency response – at least in its piston range of operation.

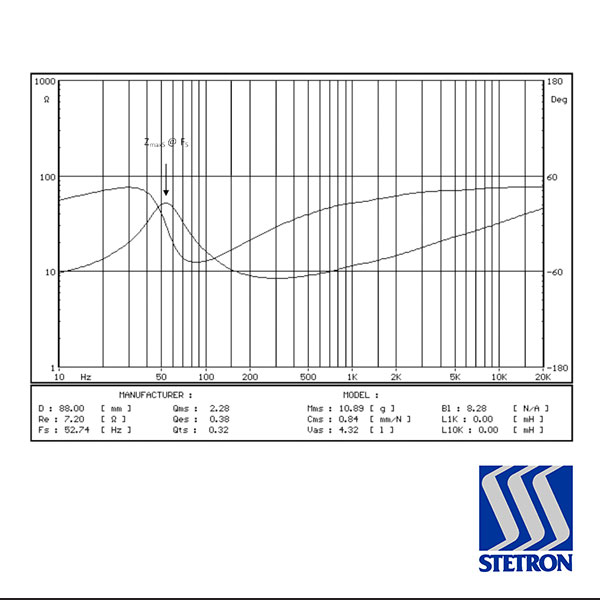

Resonance occurs at a frequency where the mechanical output (motion) of the speaker is greatest, relative to the electrical stimulus used to excite the system. For the first of the TS measurements, this resonance is examined in free air. The driver can be mounted on a simple baffle or just hanging freely. For mathematical analysis, we refer to this resonant frequency as fS. At this resonance, the impedance measured between the driver terminals peaks at a value, ZmaxS.

Now, part of this impedance (³80% of the driver’s nominal impedance) is the result of the resistance, RE, of the voice coil that interacts with the permanent magnet of the driver to generate diaphragm motion. The rate at which the impedance varies between RE and ZmaxS can be determined by the relative width of that peak in the impedance curve at resonance. With some mathematical analysis of this relationship, we can determine the damping – both mechanical and electrical – of the loudspeaker driver, QMS and QES respectively. The total damping, QTS, is the combination of these.

Once these free air parameters are measured, an additional measurement is required to determine the others. There are two options for this measurement: Add a known mass to the diaphragm or place the driver on a sealed enclosure of known internal volume and repeat the impedance reading. Each of these methods have their own nuances that, when carefully considered and controlled, provide the necessary information to determine the other key parameters needed for our model. Both of these additional parameters (mass or volume) will cause the resonant frequency to shift – the added mass lowers fS while the added enclosure increases it. We’ll consider the enclosure method.

The shifted resonant frequency, fCT, along with adjusted damping factors, QMCT and QECT, allow us to determine the remaining parameters. First, there’s the mechanical mass of the driver, MMS, representing the combined mass of the diaphragm, voice coil, and the air load driven by the diaphragm. Then, there’s the compliance of the suspension, CMS, and its analog – the compliance equivalent volume, VAS. The compliance is a measure of the stiffness of the suspension – like a spring in a car’s suspension. And the VAS describes a volume of air that exhibits a similar stiffness when compressed (ever connect two syringes with a hose and compress both at the same time? This “give” acts exactly like a spring). Finally, the motor strength – or the B·l product – is the field strength of the magnet multiplied by the length of wire in the voice coil. These can all be determined by comparison of impedance curves in these two tests and are then used to calculate the resistance, inductance, and capacitance for our model circuit. With these parameters, along with information about the speaker enclosure, an effective prediction of the system frequency response informs the design decisions required to optimize loudspeaker performance.

Have questions? Let us help. We are your source for audio solutions.

Email: contact@Stetron.com

Customer Service: Canada: 1-877-716-0751 U.S.A: 1-800-925-3002.

Log In

Log In Register

Register Favorites

Favorites